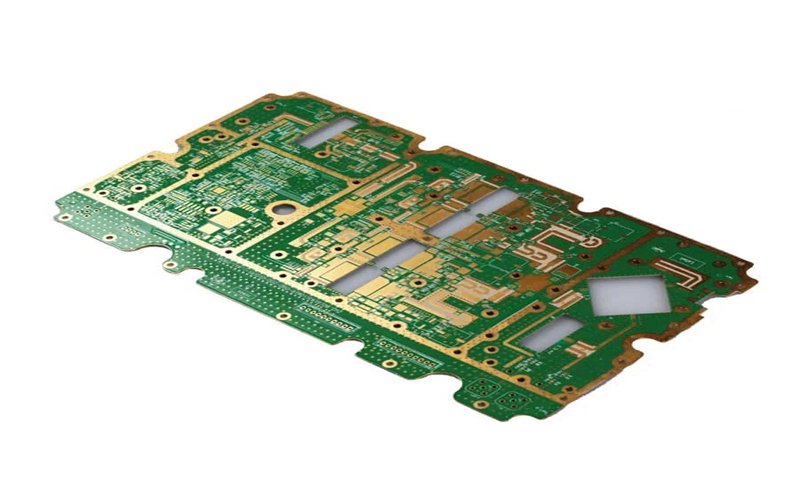

Printed Circuit Boards (PCBs) are an essential component in modern electronic devices. They provide a platform for connecting and supporting various electronic components, allowing the device to function properly. The PCB manufacturing process involves several steps that ensure the production of high-quality and reliable circuit boards. In this article, we will explore the different stages of the PCB manufacturing process.

1. Designing the PCB

The first step in the PCB manufacturing process is designing the circuit board. This involves creating a schematic diagram that outlines the connections between different components. Using specialized software, designers lay out the traces and components on the board, taking into consideration factors such as size, functionality, and manufacturability.

2. Fabricating the PCB

Once the design is finalized, the fabrication process begins. It starts with selecting the appropriate substrate material, typically a fiberglass-reinforced epoxy laminate. The substrate is then coated with a layer of copper on both sides.

The next step is to apply a layer of photosensitive material, called the solder mask, on the top side of the board. This mask protects the copper traces from oxidation and helps in soldering the components later.

After applying the solder mask, a layer of photosensitive material called the silkscreen is added. The silkscreen contains markings such as component labels, reference designators, and logos, which aid in component placement and identification.

Once the layers are applied, the board goes through a process called etching. This involves exposing the board to a chemical solution that removes the unwanted copper, leaving behind the desired circuit traces.

3. Mounting Components

After fabrication, the next step is to mount the electronic components onto the PCB. This process is known as component placement. Automated machines, known as pick-and-place machines, are used to accurately position the components on the board.

Before mounting the components, a layer of solder paste is applied to the pads on the PCB. The solder paste is a mixture of tiny solder particles and flux. It helps in bonding the components to the board during the soldering process.

Once the components are placed, the board goes through a reflow soldering process. In this process, the board is heated to a specific temperature, causing the solder paste to melt and create a strong bond between the components and the PCB.

4. Testing and Inspection

After soldering, the PCB undergoes rigorous testing and inspection to ensure its functionality and quality. Various tests, such as electrical testing and visual inspection, are performed to detect any defects or faults.

Electrical testing involves checking the connectivity of the circuit traces and verifying the functionality of the components. Visual inspection is done to identify any physical defects, such as soldering defects or component misalignment.

5. Finalizing the PCB

Once the PCB passes all the tests and inspections, it is ready for finalization. This involves applying a protective coating, called the conformal coating, to the board. The conformal coating protects the PCB from environmental factors such as moisture, dust, and corrosion.

After the conformal coating, the final step is to separate the individual PCBs from the manufacturing panel. This is done using a process called depanelization, where the PCBs are cut or scored along predefined lines.

With the completion of the finalization step, the PCB manufacturing process comes to an end. The finished PCBs are then ready to be assembled into electronic devices and play a crucial role in the functioning of various technological advancements.

In conclusion, the PCB manufacturing process involves designing the circuit board, fabricating the PCB, mounting components, testing and inspection, and finalizing the PCB. Each step is crucial in ensuring the production of high-quality and reliable circuit boards that are essential for modern electronic devices.