| Item | Speci. |

|---|---|

| Layers | 2-14 layers |

| Board thickness | 0.07mm-4.0mm |

| Material | FR-4, High TG, PI,High speed |

| Max panel size | 220*500mm |

| Min hole size | 0.1mm |

| Min line width | 0.05/0.05mm |

| Surface finish | Plated Ni/Au, ENIG, Immersion Tin,Immersion Ag, OSP etc. |

| Copper thickness | 0.5-4oz |

| Soldermask | White, Black, Blue, Green, Red etc. |

| Silkscreen | Red/Yellow/Black/White |

| Min PAD | 5mil(0.13mm) |

| Inter package | Vacuum |

| Outer package | Carton |

| Outline tolerance | ±0.075mm |

| Hole tolerance | PTH:±0.05 NPTH:±0.025 |

| Certificate | UL, IATF16949, ISO, RoHs&Reach |

| Special request | Blind hole+Gold finger + BGA |

| Material Suppilers | Shengyi, KB, Nanya, ITEQ,etc. |

| Material Suppilers | Shengyi, KB, Nanya, ITEQ,etc. |

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

- +86 0755-36991755

- +86 18129811045

- +86 0755-36991755

- sales@secircuit.com

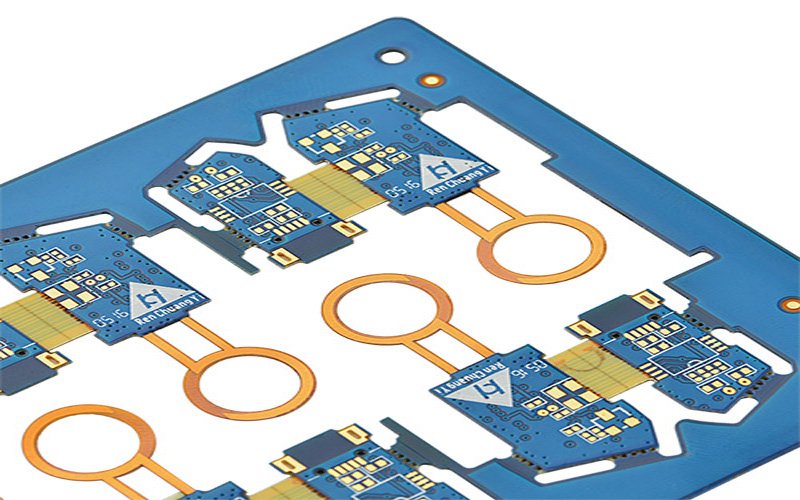

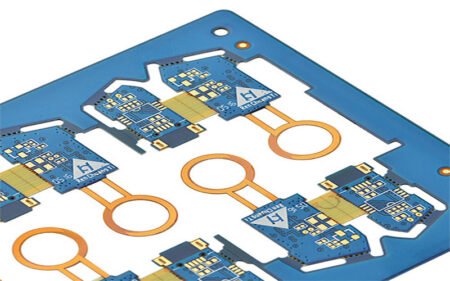

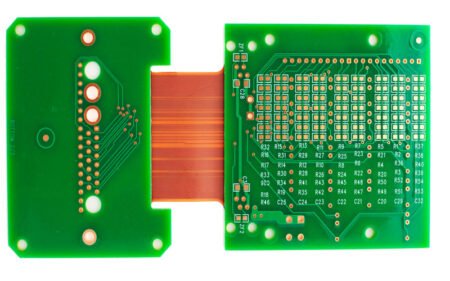

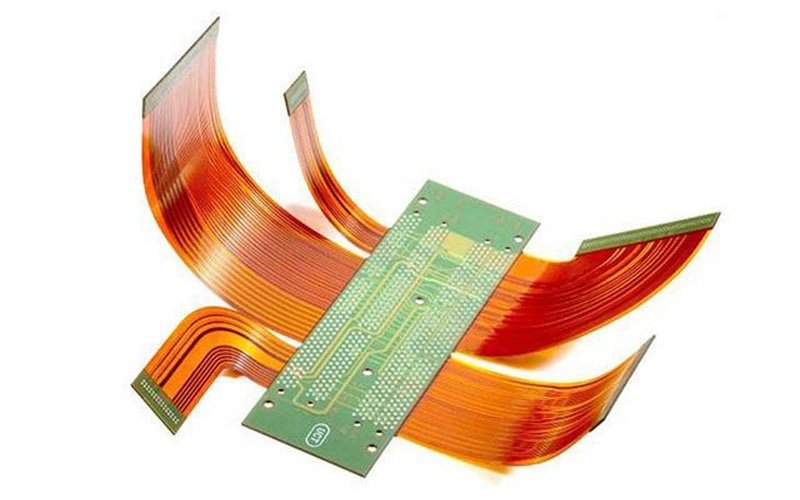

Manufacturing of Rigid-Flex PCB

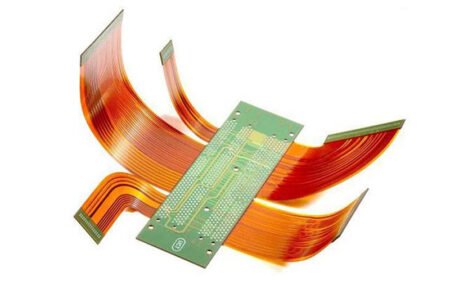

Rigid-flex printed circuit boards (PCBs) offer unique advantages and are utilized in various applications across several industries due to their ability to combine the benefits of both rigid and flexible PCBs. Here’s an analysis of some key application areas where rigid-flex PCBs are commonly used:

- Aerospace and Defense:

Avionics Systems: Rigid-flex PCBs are used in avionics systems for aircraft instrumentation, flight control systems, and communication systems due to their lightweight construction, reduced assembly complexity, and ability to withstand extreme temperatures and vibrations.

Military Applications: Military-grade rigid-flex PCBs are employed in ruggedized equipment such as radar systems, unmanned aerial vehicles (UAVs), and communication devices for defense applications, where reliability and performance in harsh environments are critical.

- Industrial Automation:

Robotics and Motion Control Systems: Rigid-flex PCBs play a crucial role in industrial automation applications by providing reliable interconnections between control units, sensors, actuators, and communication interfaces in robotic arms, CNC machines, and automated assembly lines.

IoT Devices and Sensors: Industrial IoT devices and sensor networks often utilize rigid-flex PCBs to enable seamless integration into existing machinery and infrastructure, allowing for flexible deployment and scalable expansion.

Overall, the application of rigid-flex PCBs continues to expand across various industries, driven by the need for miniaturization, lightweight designs, reliability, and flexibility in product development. As technology advances and manufacturing processes improve, rigid-flex PCBs will likely play an increasingly important role in enabling innovative solutions for diverse applications.

Consumer Electronics:

Smartphones and Wearable Devices: Rigid-flex PCBs are used in smartphones and wearable devices to accommodate complex form factors and provide reliable connections between rigid components such as processors, memory, and flexible components like display screens and batteries.

Tablets and Laptops: These devices often require compact designs with space constraints. Rigid-flex PCBs enable designers to integrate multiple rigid sections with flexible interconnects, optimizing space utilization and improving durability.

- Medical Devices:

Implantable Devices: Rigid-flex PCBs are used in medical implants such as pacemakers, defibrillators, and neurostimulators due to their ability to conform to the shape of the body and withstand repeated flexing without compromising electrical performance.

Diagnostic Equipment: Medical diagnostic equipment, including ultrasound machines, MRI scanners, and patient monitoring devices, often utilize rigid-flex PCBs to achieve compact designs, reduce weight, and improve reliability in harsh operating environments.

- Automotive Electronics:

Instrument Clusters and Infotainment Systems: Rigid-flex PCBs are employed in automotive instrument clusters, infotainment systems, and navigation displays to withstand mechanical vibrations, temperature variations, and space constraints within the vehicle dashboard.

Advanced Driver Assistance Systems (ADAS): ADAS technologies such as collision detection, lane departure warning, and adaptive cruise control rely on rigid-flex PCBs for compact integration of sensors, processors, and communication modules.