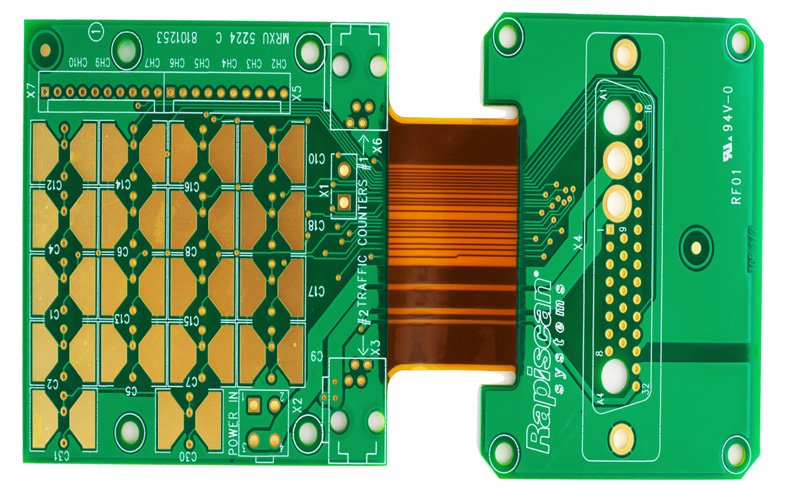

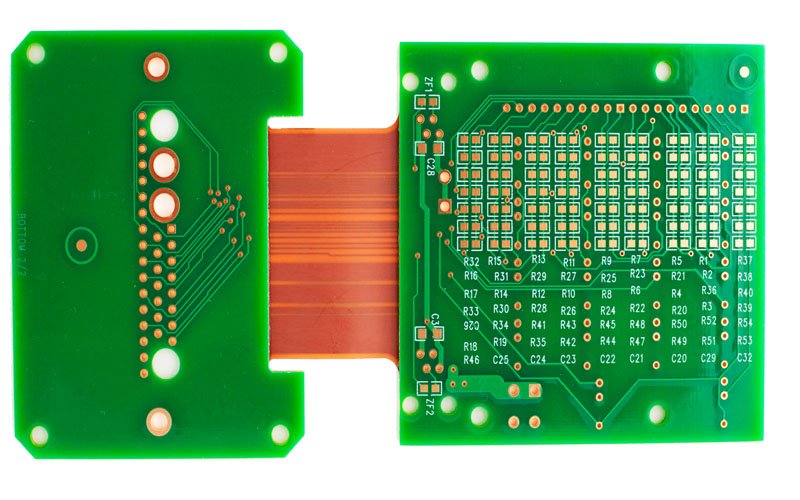

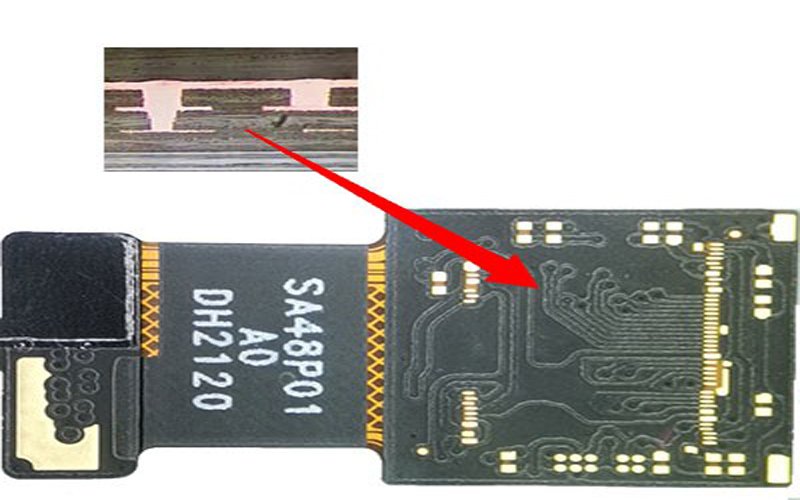

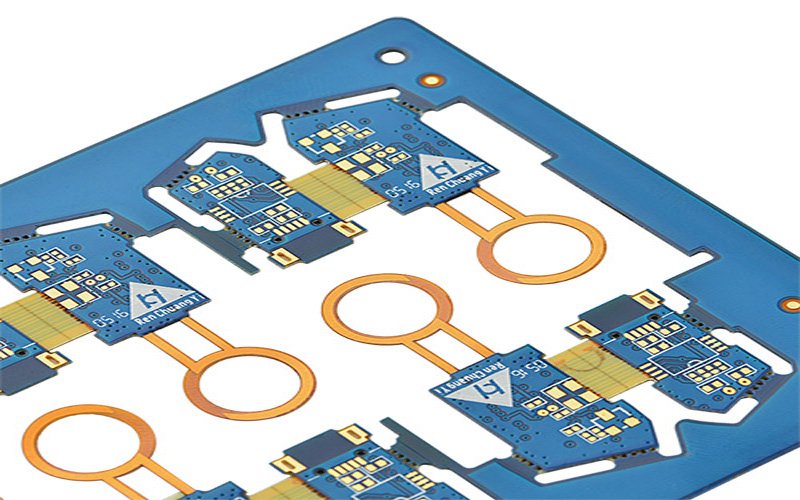

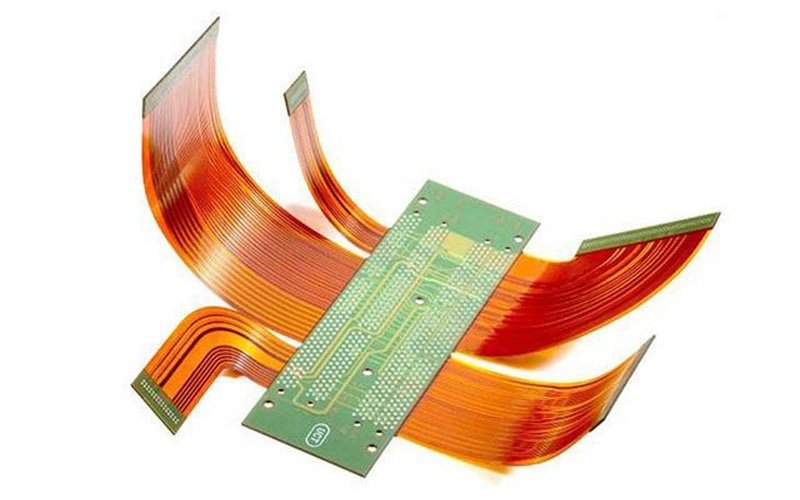

Rigid-flex board refers to a special circuit board made by pressing PCB circuit board and FPC soft board.The board materials used are mainly rigid board material FR4 and flexible board material polyimide. The rigid sections provide mechanical support and component mounting, while the flexible sections enable connections between different rigid sections and allow the PCB to bend and flex.

Rigid-flex PCBs provide a space-saving and lightweight solution for electronic devices with complex interconnections and 3-dimensional form factors. Therefore, it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area. It is of great help to reduce the internal space,reduce the volume of the finished product, and improve the performance of the product. They are commonly used in consumer electronics, automotive, aerospace, medical, and industrial applications.

Rigid-flex PCBs enable:

- Dynamic flexing, bending, folding, and wrapping

- Interconnections between multiple PCBs

- Complex, dense, and compact electronics packaging

- Rugged devices with flex-resistant cabling

- Lighter and thinner products by eliminating wires and connectors

- 3D shaping and conformability

- Reduced assembly cost by combining multiple PCBs

Compared to using discrete rigid PCBs with external cables or flex circuit interconnects, rigid-flex PCB technology provides a fully integrated solution with design, performance and reliability advantages.