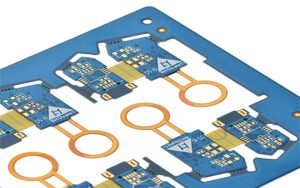

A cable flex PCB (Printed Circuit Board) serves several important functions in electronic devices and systems, particularly in applications where flexibility is required. Here are some of its key functions:

Flexibility: The primary function of a cable flex PCB is its flexibility. Unlike traditional rigid PCBs, flex PCBs are made of flexible materials such as polyimide or polyester, allowing them to bend, twist, and conform to the shape of the device or system they’re installed in. This flexibility is essential in applications where space is limited or where the PCB needs to fit into a curved or irregularly shaped enclosure.

Signal Transmission: Cable flex PCBs are often used to transmit electrical signals between different components or sections of an electronic device. They can replace traditional wire harnesses or ribbon cables, providing a more compact and lightweight solution for routing signals between various parts of the system.

Space Savings: By eliminating the need for bulky wire harnesses or rigid interconnects, cable flex PCBs help save space within electronic devices, allowing for more compact and lightweight designs. This is particularly advantageous in portable devices such as smartphones, tablets, and wearable electronics, where space is at a premium.

Reliability: Flex PCBs offer improved reliability compared to traditional wire harnesses, as they have fewer points of failure and are less prone to issues such as wire fatigue or breakage. Additionally, flex PCBs can be designed to withstand bending, vibration, and other mechanical stresses encountered in real-world applications, ensuring long-term reliability.

High-Density Interconnects: Cable flex PCBs can incorporate high-density interconnects, allowing for the routing of a large number of signals in a compact space. This makes them suitable for applications requiring a high level of integration, such as medical devices, automotive electronics, and aerospace systems.