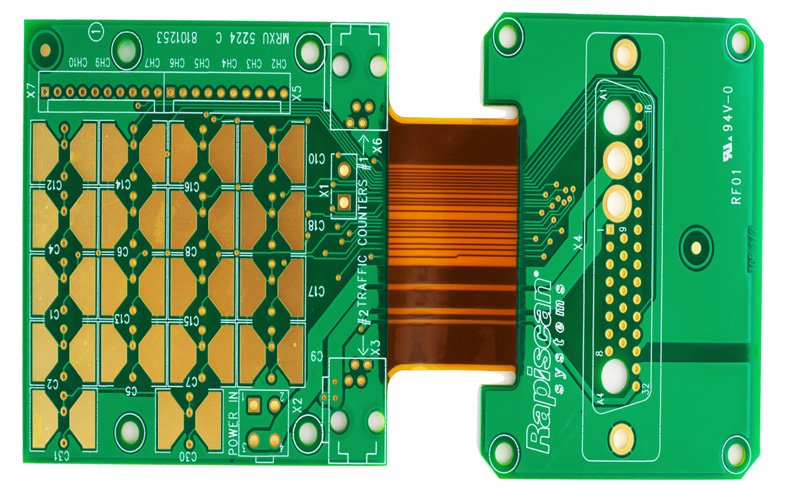

Rigid-flex PCBs, including those with cables integrated, serve several functions in electronic systems, particularly in applications where space constraints, durability, and flexibility are critical. Here are some of the primary functions of cable rigid-flex PCBs:

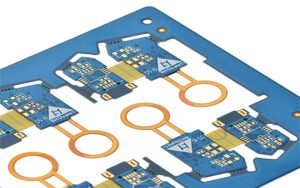

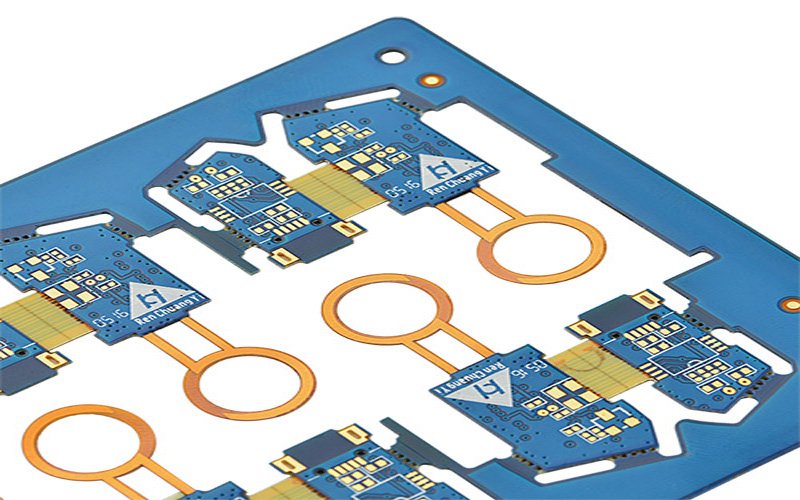

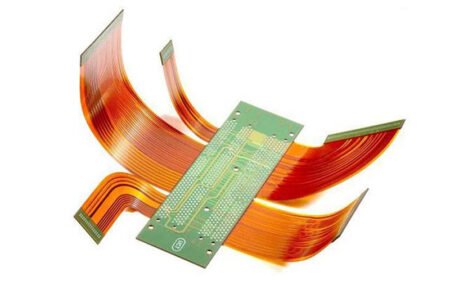

Space-saving design: Cable rigid-flex PCBs combine the advantages of rigid PCBs and flexible cables, allowing for more compact designs compared to using separate rigid PCBs and cables. This is particularly beneficial in devices with limited space, such as smartphones, wearables, and aerospace applications.

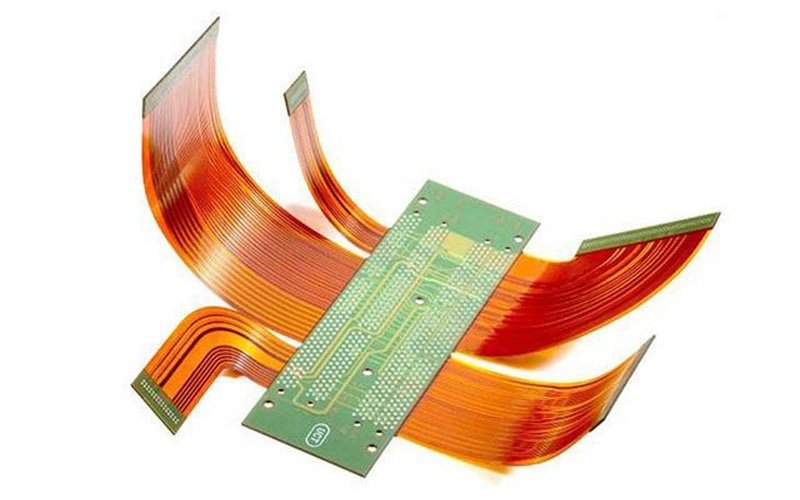

Flexibility: The flexible portions of the PCB enable bending and folding, allowing the PCB to conform to the shape of the device or accommodate movement within the system. This flexibility is essential in applications where traditional rigid PCBs would be impractical or impossible to use.

Reduced assembly complexity: Integrating cables directly into the PCB reduces the number of separate components and interconnections required in the assembly process. This simplifies manufacturing and reduces the risk of assembly errors, improving overall reliability.

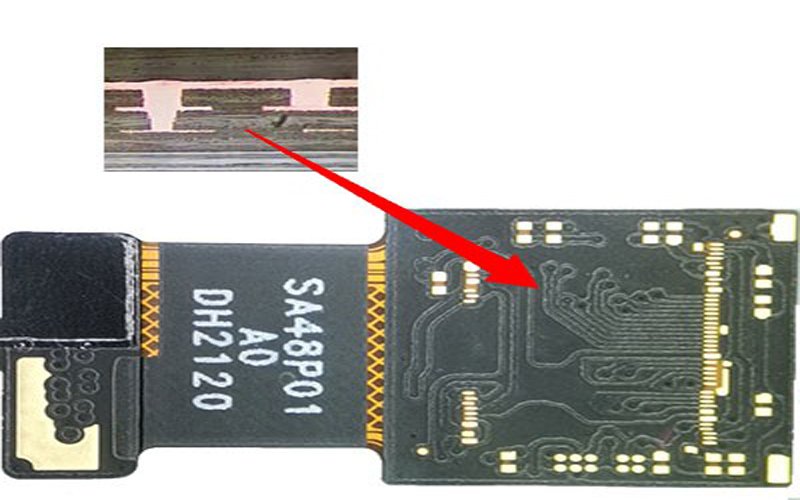

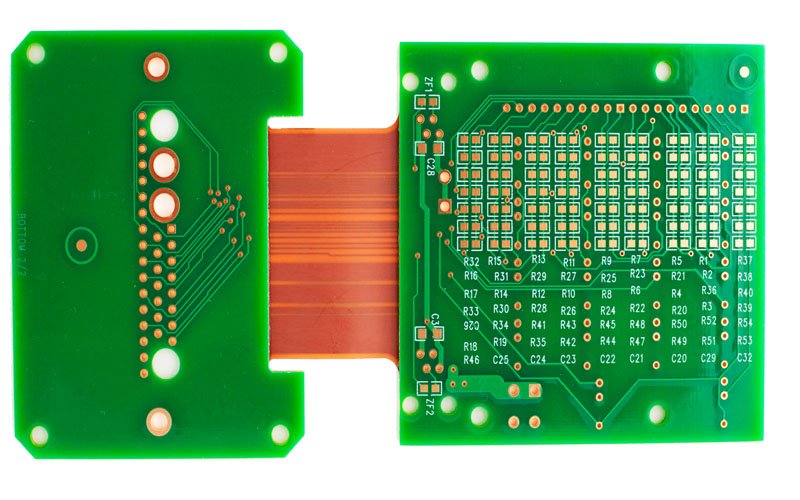

Improved reliability: Rigid-flex PCBs offer greater resistance to mechanical stress, vibration, and thermal cycling compared to traditional rigid PCBs and separate cables. The elimination of connectors and solder joints between rigid and flexible sections reduces points of failure, enhancing the reliability and longevity of the electronic system.

Enhanced signal integrity: By eliminating connectors and reducing the length of signal paths, cable rigid-flex PCBs can minimize signal losses and electromagnetic interference (EMI), leading to improved signal integrity and performance.

Protection against environmental factors: Rigid-flex PCBs can be designed to withstand harsh environmental conditions, such as moisture, dust, and temperature extremes, making them suitable for use in rugged or outdoor applications.

Customizable designs: Cable rigid-flex PCBs can be customized to meet specific design requirements, including complex shapes, multiple layers, and specialized materials. This flexibility allows for the optimization of performance, reliability, and manufacturability for a wide range of applications.