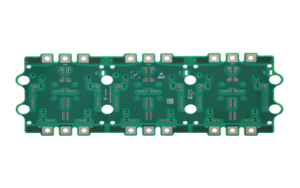

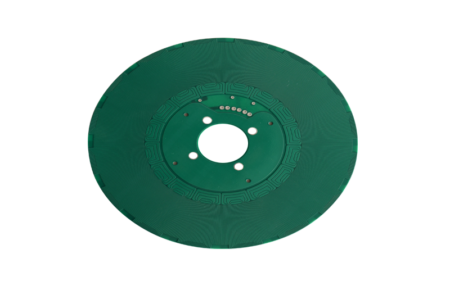

Heavy copper rigid PCBs offer several advantages over standard PCBs, particularly in applications where high current-carrying capacity, improved thermal management, and increased mechanical strength are required. Some of the key advantages of heavy copper rigid PCBs include:

High Current-Carrying Capacity: Heavy copper PCBs are designed with thicker copper layers than standard PCBs, typically ranging from 2 to 20 ounces or more per square foot. This increased copper thickness allows heavy copper PCBs to carry higher currents without overheating, making them ideal for power electronics, motor drives, and other high-current applications.

Improved Thermal Management: The thicker copper layers in heavy copper PCBs provide better thermal conductivity and heat dissipation properties compared to standard PCBs. This allows heavy copper PCBs to efficiently dissipate heat generated by high-power components, reducing the risk of overheating and prolonging the lifespan of the electronic device or system.

Enhanced Mechanical Strength: The additional copper material in heavy copper PCBs increases their mechanical strength and rigidity, making them more resistant to bending, warping, and mechanical stress. This makes heavy copper PCBs suitable for applications where the PCB may be subjected to mechanical shock or vibration, such as automotive electronics, industrial control systems, and aerospace applications.

Improved Current Density: Heavy copper PCBs can accommodate higher current densities compared to standard PCBs, thanks to their thicker copper layers and wider traces. This allows for more compact and efficient designs, as well as the integration of higher-power components into the PCB assembly.

Reduced Voltage Drop: The lower resistance of heavy copper traces reduces voltage drop across the PCB, improving the efficiency and performance of the electronic circuit. This is particularly important in high-power applications where minimizing voltage drop is critical for maintaining system stability and reliability.

Reliability and Longevity: Heavy copper PCBs are designed to withstand harsh operating conditions and environmental factors, thanks to their robust construction and enhanced thermal management capabilities. This results in improved reliability and longevity, reducing the risk of premature failure and downtime in mission-critical applications.

the advantages of heavy copper rigid PCBs, including their high current-carrying capacity, improved thermal management, enhanced mechanical strength, higher current density, reduced voltage drop, and reliability, make them well-suited for a wide range of high-power and high-reliability applications.