PCB Assembly

Yuanjin Technology is one of the leading PCB manufacturing & Assembly supplier in China with more than 10 years experience,we offer one-stop PCB manufacturing services, from design to manufacturing. We produce PCB prototype to small/medium/large quantities of 1-32 layer printed circuit boards, including rigid PCB, flex PCB, rigid-flex,single/double layer PCB. multilayer PCB, HDI PCB, aluminum PCB, thick copper PCB, high frequency PCB , High TG PCB, Ceramic PCB and so on.

We guarantee 100% PCB fabricaiton reliability. All PCB boards are produced according to 94v0, IPC-6012 standards and inspected according to IPC-A-600 in the latest version for electronics industry.

Currently we have over 10,000+ electronic contract customers worldwide. You can trust Ucreate International to meet your demands.

- Assembly Process Planning: Develop a detailed plan for the PCB assembly process, including component placement, soldering techniques (SMT, THT, BGA, etc.), testing procedures, and quality control measures. Consider factors such as component compatibility, assembly efficiency, and reliability.

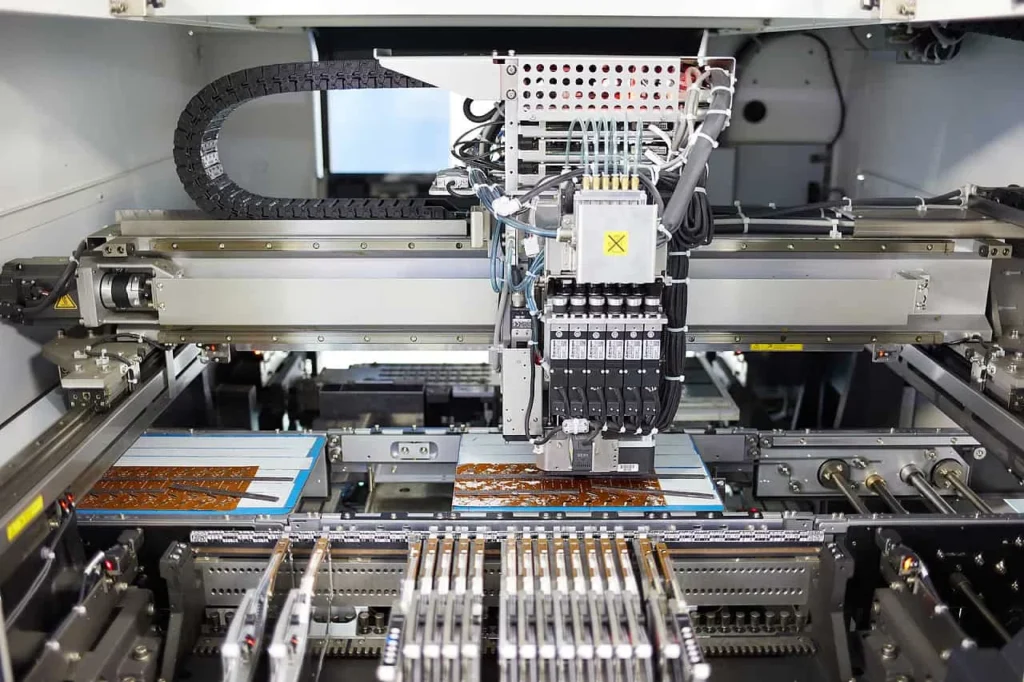

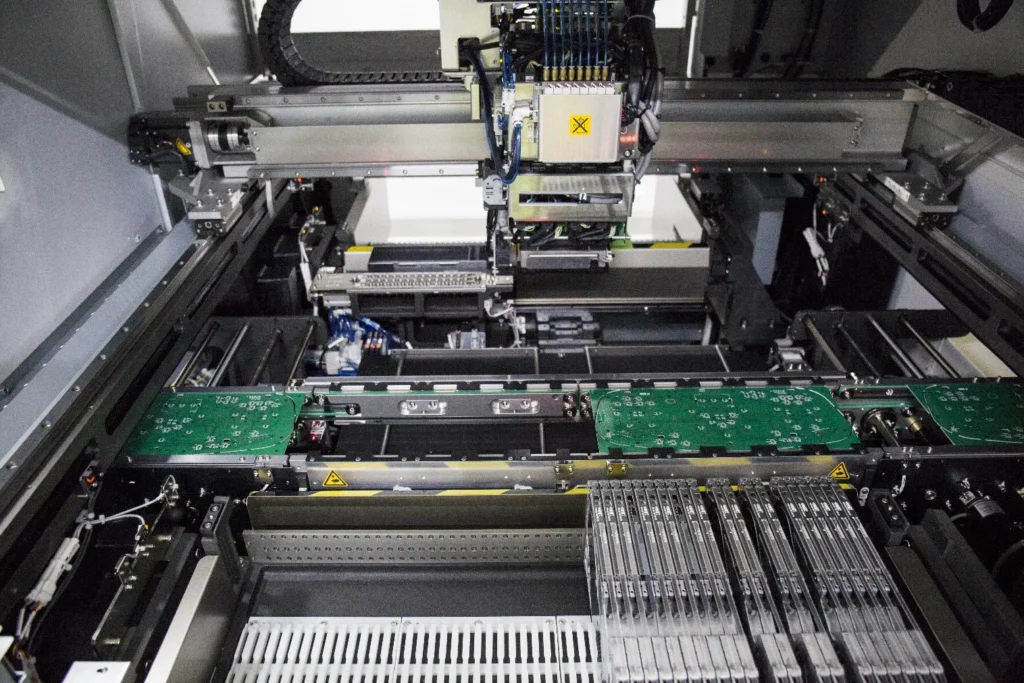

- Assembly Execution: Carry out the PCB assembly according to the established plan. Utilize automated assembly equipment and skilled technicians to ensure accuracy and efficiency. Follow best practices for handling components, soldering, and quality assurance.

- Testing and Inspection: Perform comprehensive testing and inspection of the assembled PCBs to verify functionality and quality. Use a combination of automated testing equipment (AOI, ICT, etc.) and manual inspection to detect any defects or issues.

Full Turn-Key PCBAssembly

Yuanjin Technology provides full turn-keyassembly and involves managing all aspects of the PCB assembly process, from component procurement to final testing and delivery. Here’s a step-by-step guide on how to provide Full Turn-Key PCB Assembly services:

- Customer Requirements Analysis: Understand the customer’s requirements thoroughly. This includes the specifications for the PCB design, the bill of materials (BOM), quality standards, quantity needed, timeline, and any special considerations.

- Component Sourcing: Source all the necessary electronic components specified in the BOM. Establish relationships with reliable suppliers to ensure timely delivery and quality components. Negotiate pricing and terms to optimize cost-effectiveness.

- PCB Fabrication: Arrange for the fabrication of the bare PCBs based on the design files provided by the customer. Work closely with PCB manufacturers to ensure that the boards meet the required specifications, including size, layer count, material, and surface finish.

| PCB Assembly Capability | ||||

|---|---|---|---|---|

| Item | Lot Size | |||

| Normal | Special | |||

| PCB(used for SMT)spec | (L*W) | Min | L≥3mm | L<2mm |

| W≥3mm | ||||

| Max | L≤1200mm | L > 1200mm | ||

| W≤500mm | W> 500mm | |||

| (T) | Min thickness | 0.2mm | T<0.1mm | |

| Max thickness | 4.5mm | T>4.5mm | ||

| SMT components spec | outline dimension | Min size | 201 | 1005 |

| (0.6mm*0.3mm) | (0.3mm*0.2mm) | |||

| Max size | 200mm*125mm | 200mm*125mm<SMD | ||

| component thickness | T≤6.5mm | 6.5mm<T≤15mm | ||

| QFP、SOP、SOJ | Min pin space | 0.4mm | 0.3mm≤Pitch<0.4mm | |

| (multi pins) | ||||

| CSP,BGA | Min ball space | 0.5mm | 0.3mm≤Pitch<0.5mm | |

| DIP PCB SPEC | (L*W) | Min Size | L≥50mm | L<50mm |

| W≥30mm | ||||

| Max Size | L≤1200mm | L≥1200mm | ||

| W≤500mm | W≥500mm | |||

| (T) | Minimum Thickness | 0.8mm | T<0.8mm | |

| Maximum Thickness | 2mm | T>2mm | ||

| BOX BULID | FIRMWARE | Provide programming firmware files,Firmware + software installation instructions | ||

| Function test | Level of testing required along with test instructions | |||

| Plastic & Metal Casings | Metal Casting,Sheet Metal work, Metal Fabrication, Metal and plastic extrusion | |||

| BOX BUILD | 3D CAD model of enclosure + specifications | |||

| (include drawings, size, weight, colour, material, finish, IP rating, etc) | ||||

| PCBA FILES | PCB FILE | PCB Altium/Gerber/Eagle files | ||

| (Including specs such as thickness, copper thickness, solder mask colour, finish, etc) | ||||