| Item | Speci. |

|---|---|

| Layers | 1-4 layers |

| Board thickness | 0.07mm-4.0mm |

| Material | FR-4,CEM-1/CEM-3,PI,High Tg,Rogers |

| Max panel size | 220mm×500mm |

| Min hole size | 0.1mm |

| Min line width | 0.05 / 0.05mm |

| Surface finish | Plated Ni/Au, ENIG, Immersion Tin,Immersion Ag, OSP etc. |

| Copper thickness | 0.5-4oz |

| Soldermask | Green/Yellow/Black/White/Red/Blue |

| Silkscreen | White, Black, Blue, Green, Red etc. |

| Min PAD | 5mil(0.13mm) |

| Inter package | Vacuum |

| Outer package | Carton |

| Outline tolerance | ±0.1mm |

| Hole tolerance | PTH:±0.05 NPTH:±0.025 |

| Certificate | UL, IATF16949, ISO, RoHs&Reach |

| Special request | Blind hole+Gold finger + BGA |

| Routing & Scoring | V-cut / Tab-routing/ Individual routing |

| Electrical Testing | Continuity & isolation, impedance control, Hi-Pot, etc. |

| Special Request | Blind hole+Gold finger + BGA |

| Certification | UL, IATF16949, ISO, RoHs&Reach |

| Material Suppilers | Shengyi, KB, Nanya, ITEQ,etc. |

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

- +86 0755-36991755

- +86 18129811045

- +86 0755-36991755

- sales@secircuit.com

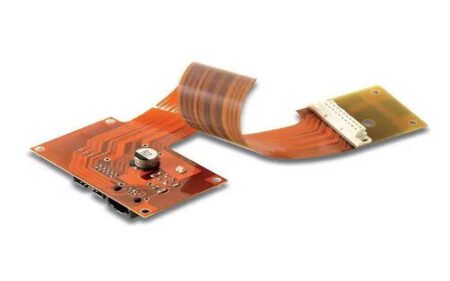

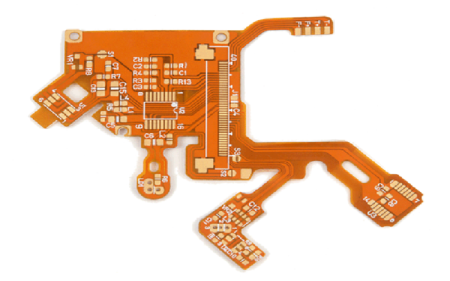

Manufacturing of Flex PCB

Guaranteeing a high-quality flex printed circuit board (PCB) product involves attention to detail, adherence to best practices, and rigorous quality control measures throughout the manufacturing process.

Quality Control:

Implement stringent quality control measures throughout the manufacturing process, including monitoring of process parameters, material inspection, and documentation control.

Establish traceability systems to track materials, components, and manufacturing processes to facilitate root cause analysis and continuous improvement.Environmental Considerations:

Consider environmental factors such as temperature, humidity, and mechanical stress during both manufacturing and application.

Perform reliability testing under simulated operating conditions to evaluate the long-term performance and durability of the flex PCB product.Compliance and Certification:

Ensure compliance with relevant industry standards and regulations, such as IPC (Association Connecting Electronics Industries) standards and UL (Underwriters Laboratories) certification for safety and reliability.Obtain necessary certifications or approvals for specific applications or markets, such as automotive, aerospace, or medical devices.

Yuanjin Technology are some key steps to ensure the production of high-quality flex PCBs:

Material Selection:

Choose high-quality flexible substrate materials that offer good mechanical properties, such as polyimide (PI) or polyester (PET).

Select appropriate copper foil thickness and quality to ensure good electrical performance and reliability.Manufacturing Processes:

Employ specialized manufacturing processes designed for flex PCBs, such as roll-to-roll fabrication for mass production or laser cutting for precise outline definition.

Use adhesives and coverlay materials specifically formulated for flexible substrates to ensure good adhesion and mechanical stability.Flexible Circuit Assembly:

Follow best practices for component placement and soldering techniques, taking into account the flexibility of the PCB.

Use flexible solder mask materials that can withstand repeated bending without cracking or delamination.

Testing and Inspection:Testing and Inspection:

Conduct thorough testing and inspection at various stages of the manufacturing process, including bare board testing, electrical testing, and visual inspection.

Utilize advanced testing techniques such as impedance testing and microsection analysis to ensure compliance with specifications and standards.