| PCB Assembly Capability | ||||

|---|---|---|---|---|

| Item | Lot Size | |||

| Normal | Special | |||

| PCB(used for SMT)spec | (L*W) | Min | L≥3mm | L<2mm |

| W≥3mm | ||||

| Max | L≤1200mm | L > 1200mm | ||

| W≤500mm | W> 500mm | |||

| (T) | Min thickness | 0.2mm | T<0.1mm | |

| Max thickness | 4.5mm | T>4.5mm | ||

| SMT components spec | outline dimension | Min size | 201 | 1005 |

| (0.6mm*0.3mm) | (0.3mm*0.2mm) | |||

| Max size | 200mm*125mm | 200mm*125mm<SMD | ||

| component thickness | T≤6.5mm | 6.5mm<T≤15mm | ||

| QFP、SOP、SOJ | Min pin space | 0.4mm | 0.3mm≤Pitch<0.4mm | |

| (multi pins) | ||||

| CSP,BGA | Min ball space | 0.5mm | 0.3mm≤Pitch<0.5mm | |

| DIP PCB SPEC | (L*W) | Min Size | L≥50mm | L<50mm |

| W≥30mm | ||||

| Max Size | L≤1200mm | L≥1200mm | ||

| W≤500mm | W≥500mm | |||

| (T) | Minimum Thickness | 0.8mm | T<0.8mm | |

| Maximum Thickness | 2mm | T>2mm | ||

| BOX BULID | FIRMWARE | Provide programming firmware files,Firmware + software installation instructions | ||

| Function test | Level of testing required along with test instructions | |||

| Plastic & Metal Casings | Metal Casting,Sheet Metal work, Metal Fabrication, Metal and plastic extrusion | |||

| BOX BUILD | 3D CAD model of enclosure + specifications | |||

| (include drawings, size, weight, colour, material, finish, IP rating, etc) | ||||

| PCBA FILES | PCB FILE | PCB Altium/Gerber/Eagle files | ||

| (Including specs such as thickness, copper thickness, solder mask colour, finish, etc) | ||||

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

- +86 0755-36991755

- +86 18129811045

- +86 0755-36991755

- sales@secircuit.com

How to provide a good and high-quality PCBA products?

Providing a good and high-quality Printed Circuit Board Assembly (PCBA) involves attention to detail, adherence to best practices, and rigorous quality control measures throughout the manufacturing process.

Experienced Assembly Team:

Employ skilled and experienced technicians and engineers who are proficient in PCBA manufacturing processes.

Provide ongoing training to keep the assembly team updated on the latest technologies and best practices.Traceability and Documentation:

Establish traceability systems to track components, materials, and processes throughout the manufacturing lifecycle.

Maintain comprehensive documentation of all manufacturing processes, including assembly instructions, test procedures, and inspection records.GoodContinuous Improvement:

Regularly review and analyze manufacturing data to identify areas for improvement.

Implement corrective and preventive actions to address any issues or defects that arise during production.

Yuanjin Technology are some key steps to ensure the production of a high-quality PCBA product:

Select Reliable Components:

Source components from reputable suppliers to ensure quality and reliability.

Conduct thorough component sourcing and verification to avoid counterfeit or substandard components.Strict Quality Control:

Implement stringent quality control procedures at every stage of the manufacturing process.

Utilize automated inspection equipment such as AOI and X-ray inspection to detect defects and ensure solder joint quality.

Perform functional testing to verify the proper operation of the assembled PCBs.Use Advanced Assembly Techniques:

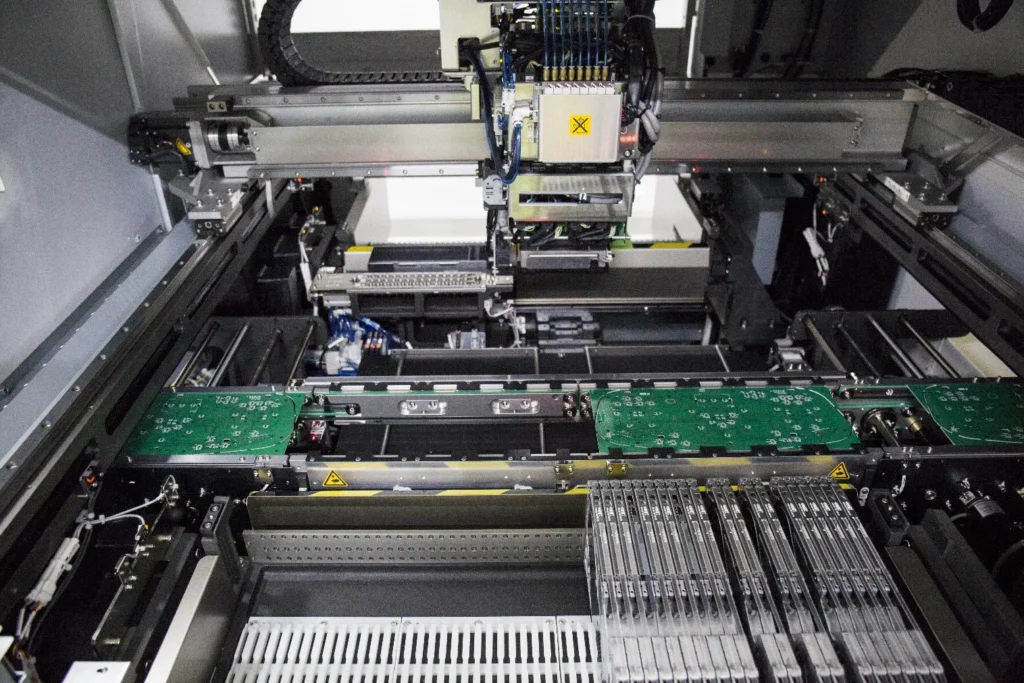

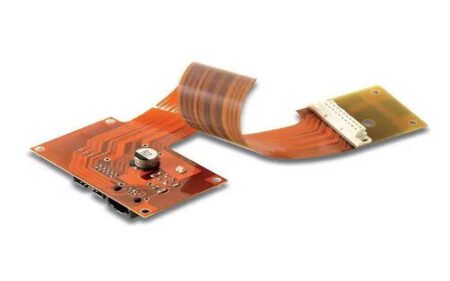

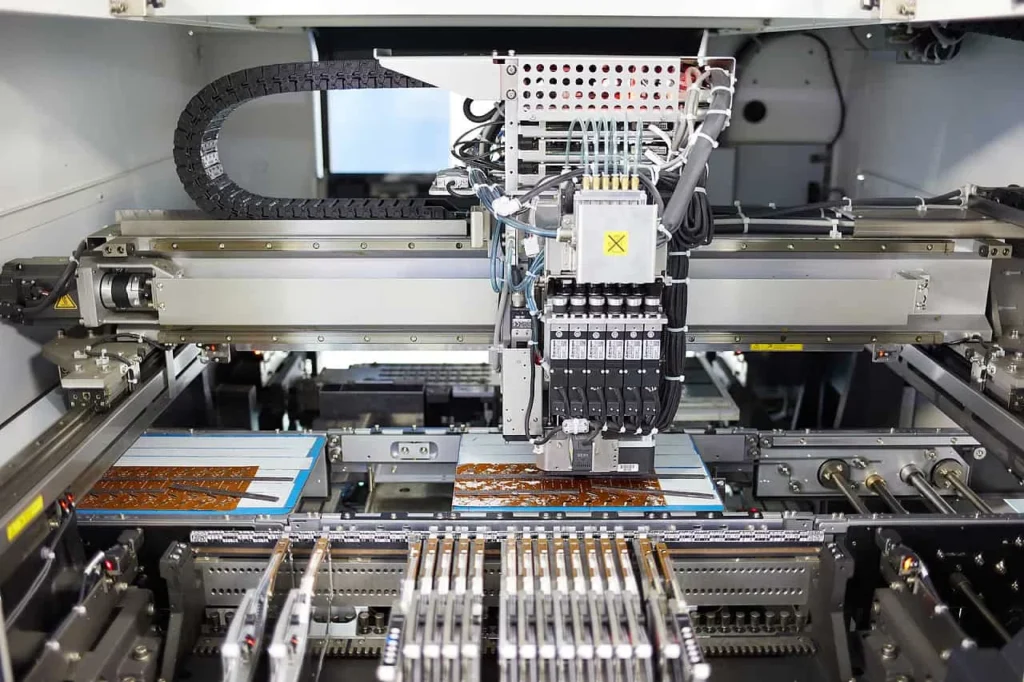

Employ advanced assembly techniques such as surface mount technology (SMT) for precise component placement and soldering.

Optimize solder paste deposition using laser-cut stencils to ensure accurate and consistent solder joints.